-

Our products

-

View all products

-

HexAuFoil QUANTIFOIL® Holey Carbon Supports for Cryo-EM UltrAuFoil® Holey Gold Sample Supports Additional Ultrathin Continuous Carbon Layer Conventional & Continuous Carbon Films SiO2 Films Custom Cryo-EM Sample Supports and Special Treatments QUANTIFOIL® Active How our supports are packed for shipment

-

-

View all products

- Our company

- News and social updates

- Support

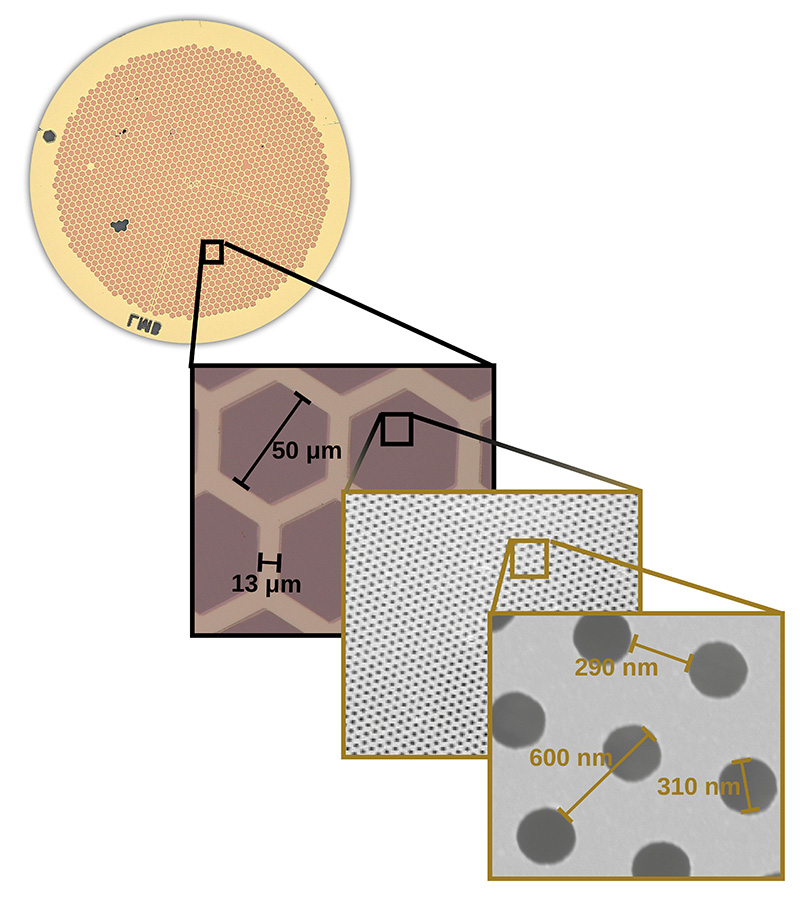

HexAuFoil® ultra-small hole gold grids

Improve every image with our revolutionary, optimized, ultra-small hole support geometry.

What is unique to HexAuFoil?

With it's revolutionary small-hole, all-gold design, it allows for virtually-movement free imaging creating zero dose reconstructions for the first time. HexAuFoil's unique high-density, hexagonal design and improved stability means less re-focusing and faster data collections.

HexAuFoil is ideal for cryo-EM scientists in industry or academia looking to maximize output of high-quality reconstructions for SBDD and academic research.

Over the last decade, the increasing use of cryoEM has driven a demand for ever higher quality data. One source of information loss and map quality reduction is particle movement. While data processing can reduce the effect of this issue, novel sample preparation techniques can eliminate it. Investigations by the team led by Dr Chris Russo at MRC Laboratory of Molecular Biology, Cambridge were able to conclude that a key factor was reducing the size of the holes on a grid to 300 nm: roughly 10 times the desired 30 nm ice thickness. Delivering holes this small required the development of a completely new manufacturing process, and led to the launch of HexAuFoil® ultra-small hole gold supports: invented at the MRC LMB, and commercialized by Quantifoil, part of SPT Labtech.

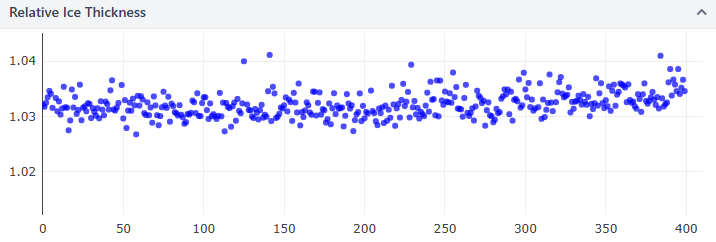

The new process not only delivered movement-free imaging (as illustrated below), but also a step-change in grid specification, with hole diameter variation as little as 10 nm, and grid bar and thickness similarly controlled. The unrivaled consistency of HexAuFoil leads to consistently thin ice: ice variation across a dataset can be as little as 1%, at a thickness of 35 nm +/- 7 nm. Other processing parameters show similar improved consistency, resulting in simpler data processing. Taken together, these benefits enable high quality, high resolution datasets to be collected with as few as 400 movies, despite the smaller holes meaning fewer particles per movie. Finally, the consistent ice means that a much larger number of holes in each hexagon can be collected, and this combined with the unique densely-packed hexagonal design results in data collection times can be as much as halved.

With better data, faster, in a small number of images, we are proud to say HexAuFoil delivers better data every image.

.png)

Pristine wafer

Off-phase lithography used to create 4 inch wafers. Each wafer has approximately 600 grids with 290 nm round holes with 300 nm separation in a hexagonal array.

Cryo-evaporator

Copper/gold evaporation onto wafer at liquid nigtrogen temperatures. Up to 5 wafers/day.

Gold electroplating

Up to 1 μm/15 mi.

Release from wafer

Strong, hot base to etch silicon wafer away.

Piranha

Removes non-gold contamination from grid.

Grid rinsing

Thoroughly dried

Quality control

Every grid inspected by light microscopy. Batch level TEM and SEM inspection